STMicroelectronics has released a set of antenna-matching companion chips for STM32WL33 wireless microcontrollers (MCUs) to simplify the development of IoT, smart-metering, and remote-monitoring applications.

The new MLPF-WL-01D3/02D3/04D3 ICs combine impedance matching and harmonic filtering on a single glass substrate to optimise the main radio’s RF performance, leveraging proprietary integrated passive device (IPD) technology. Precision engineered and housed in an ultra-compact package, the highly integrated devices ensure right-first-time design while saving development time, bill-of-materials costs, and board space.

Integrating antenna protection, the new devices substantially simplify the RF connection to the MCU. In addition to ensuring optimal performance, integrated matching and filtering also increases reliability and reduces overall cost by eliminating the need to combine multiple discrete components.

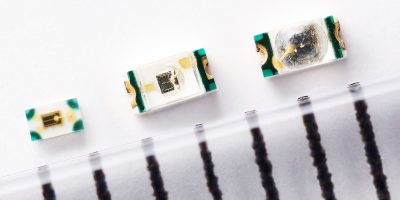

In total, there will be seven variants, letting designers optimise for radio operation in high-band (826-958MHz) or low-band (413-479MHz), high-power (16dBm/20dBm) or low-power (10dBm), and for 4-layer or 2-layer PCB designs. The non-conductive glass substrate ensures outstanding performance with minimal temperature drift, and the chip-scale package has extremely compact dimensions, measuring just 1.47mm x 1.87mm and 630µm high after reflow.

The long-range sub-GHz radio of ST’s STM32WL33 wireless MCUs can operate in either of the 413-479MHz and 826-958MHz license-free bands and with up to 20dBm output power where local regulations permit. With an Arm® Cortex®-M0+ core and selected peripherals also on-chip, the highly integrated wireless MCUs simplify the design of remote-monitoring equipment for smart city, smart agriculture, and smart industry. Applications include smart meters, and safety systems, asset-trackers, and proximity detection. A set of reference designs (STDES-WL3xxxx), pre-certified and fine-tuned for STM32WL33 MCUs, is also available.