Aerospace and defence applications rely on Position, Navigation and Timing (PNT) technology for mission-critical accuracy and reliability. However, integrating PNT into a design requires extensive domain knowledge in this area. To fast track the development process, Microchip has announced its portfolio of GNSS Disciplined Oscillator (GNSSDO) Modules that integrate the company’s embedded atomic clock and oscillator technologies, including the Chip-Scale Atomic Clock (CSAC), Miniature Atomic Clock (MAC) and Oven-Controlled Quartz Crystal Oscillators (OCXOs).

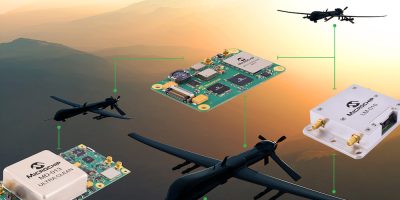

The GNSSDO modules process reference signals from GNSS or an alternative clock source and disciplines the on-board oscillator to the reference signal, enabling precise timing, stability and holdover performance based on end application requirements. These GNSSDOs are used in military and defence applications such as radar, satellite communications (SATCOM), mounted and dismounted radios, vehicle platforms and other critical PNT applications including GNSS-denied environments.

A GNSSDO module acts as a PNT subsystem within a larger system design or as a stand-alone system, providing precise timing that is critical to any high-performance system. The local oscillators used in the GNSSDO modules are engineered and manufactured by Microchip, ensuring customers have a product that they can trust. Other Microchip components on the module include 32-bit microcontrollers (MCUs) and SmartFusion® 2 FPGAs.

Microchip’s newly released GNSSDO modules include:

• The MD-013 ULTRA CLEAN is Microchip’s highest performance standard GNSSDO module that can support multiple GNSS constellations, including GPS, Galileo, BeiDou, and NavIC or an external reference input. This module is designed around a high-performance OCXO that enables outputs with ultra-low phase noise and short-term frequency stability characteristics. The respective specifications for phase noise performance are −119 dBc/Hz at a 1 Hz offset and noise floor of −165 dBc/Hz. Short-term frequency stability, measured by Allan Deviation (ADEV), is 3E-13 at 1s tau, 6E-13 at 10s tau and 9E-13 at 100s tau.

This module can generate 1 PPS TTL, 10 MHz sine wave and 10 MHz square wave outputs that are disciplined to an embedded 72-channel single-band GNSS receiver, with the option to upgrade to a configurable L1/L2 or L1/L5 dual-band, multi-GNSS receiver.

• The MD-300 is Microchip’s GNSSDO module for harsh environments, available in a small 1.5 × 2.5-inch footprint. The MD-300 has an embedded MEMS OCXO or TCXO as the local oscillator, enabling low g-sensitivity, high shock and vibration tolerance and low thermal transient response. Due to its Size, Weight and Power (SWaP) performance, the MD-300 is well-suited for applications like drones and manpacks. The module can discipline to an embedded GNSS receiver or external reference and output high- performance 10 MHz and 1 PPS signals.

• The LM-010 is a PPS disciplined module that provides precise timing for Low Earth Orbit (LEO) applications that demand radiation tolerance coupled with stability and holdover capability. As a standard platform module, the LM-010 provides both 1 PPS TTL and 10 MHz sinewave outputs that are disciplined to an external reference input. Internal to the module is Microchip’s digitally corrected OCXO or low-power CSAC SA.45.

Microchip’s GNSSDO modules utilise a common serial communication protocol and Graphical User Interface (GUI) for command and control of the unit. A variety of parameters can be configured through the software including inputs, outputs, auto switching, holdover parameters, GNSS tracking and observables, as well as reporting messages coming off the serial interface.

Development Tools

The GNSSDO portfolio is supported by Microchip’s VDOM3 software and GUI to help developers adjust performance parameters of the GNSSDO modules and quickly test integrating these products into their systems. The MD-01X Evaluation Kit is also available to easily connect and monitor the MD-01 series of GNSSDOs.

https://www.microchip.com