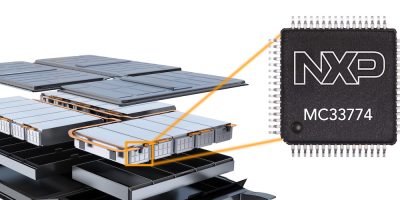

NXP has introduced its next-generation battery cell controller IC, designed to optimise battery management systems (BMS) performance and safety. With down to 0.8 mV cell measurement accuracy and maximum cell balancing capability over a wide temperature range, NXP’s MC33774 18-channel analog front-end device comes with ASIL D support for use in safety-critical, high-voltage lithium-ion (Li-ion) batteries to maximise the usable capacity.

Li-ion batteries are commonly used in EVs because of their high energy density by volume and weight, low self-discharge, low maintenance, and ability to sustain thousands of charge-discharge cycles. They account for approximately 30 to 40 percent of the total cost of the EV. A typical 800 V Li-ion battery system comprises around 200 individual cells connected in series. It is critical to accurately estimate the battery pack’s state-of-charge (SoC) at any given temperature and instant in the years-long life-cycle. NXP’s MC33774 is designed to deliver lifetime accurate cell measurement data in temperatures ranging from -40°C to +125°C, enabling very precise range predictions.

“The MC33774 has undergone a rigorous design and validation process to ensure its safety and reliability in automotive use,” said Robert Li, Vice President and General Manager, Product Line Driver and Energy Systems at NXP. “This includes system-level validation to test electromagnetic compatibility, electrostatic discharge, transient immunity, and communication reliability in demanding scenarios. The MC33774 is designed to reduce costs for OEM systems while maintaining its reliability, allowing for a safe launch of cars despite shorter development cycles in the EV industry.”

Based on NXP’s SmartMOS SOI (Silicon-on-Isolator) technology, the MC33774 Li-ion battery cell controller offers cell measurement accuracy down to ±0.8 mV, which helps to ensure lifetime performance with both nickel manganese cobalt (NCM) and lithium iron phosphate (LFP) cell chemistries. The precision design and calibration technologies of the NXP MC33774 save customers end-of-line (EoL) calibration costs.

The NXP MC33774 18-channel Li-ion battery controller IC is part of the NXP High Voltage BMS chip-set solution, which includes future products like the MC33777, a battery junction box controller for pack level measurement, and the already released MC33665 battery management communication gateway. The comprehensive and robust BMS system solution offers first-time-right battery systems while working to avoid field incidental surprises. The complete design package, which includes production-grade software and functional safety libraries, helps to accelerate the development time of functional safety systems and saves system bill-of-material costs.