ST is enhancing smart computer vision with its latest global-shutter image sensor. The global-shutter sensor technology is particularly useful for capturing distortion-free images when the scene is moving or when near-infrared illumination is used.

“Our new global-shutter image sensor provides superb resolution in an extremely small die suitable for use in equipment like smart glasses and AR/VR headsets. It’s also well suited to personal and industrial robotics and smart-home devices. All these applications benefit from the sensor’s high performance, small size, ultra-low power consumption, and optimised cost,” said Alexandre Balmefrezol, Executive Vice President, Imaging Sub-Group General Manager, STMicroelectronics.

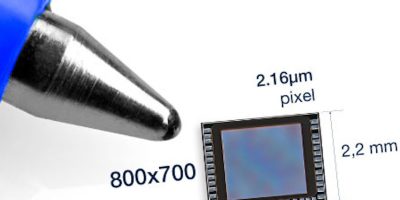

The sensor is small, measuring just 2.7mm x 2.2mm, and has a native resolution of 800 x 700 pixels. Its low power consumption means it can be used with smaller batteries, and its imaging performance is exceptional, with high contrast and superior image clarity.

The sensor also offers event-like image streaming, making it ideal for eye-tracking and other motion-estimation use cases.

This new global-shutter image sensor also comes with innovative embedded features. These features include native background removal, which reduces the post-processing workload for the host. The sensor also has an ‘always-on’ 1mW autonomous mode that allows continuous awareness even when the host is turned off, saving power. The system wakes up when a movement or scene change is detected.

ST’s new VD55G1 is sampling now, with volume production slated for March 2024.

For more information, please go to https://www.st.com/en/imaging-and-photonics-solutions/vd55g1.html