Ceva has announced that Alif Semiconductor has licensed and deployed the Ceva-Waves Bluetooth Low Energy and 802.15.4 IPs in its Balletto family of wireless microcontrollers.

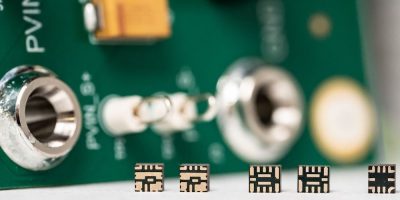

The Balletto family is a complete Edge AI/ML microcontroller solution for connected IoT platforms with integrated Bluetooth Low Energy 5.3 and 802.15.4 wireless subsystem and a dedicated network co-processor, enabling connectivity and machine learning in a single chip. The Balletto family delivers up to 50x boost in machine learning performance and inference efficiency versus traditional MCUs that lack neural co-processors. The Ceva-Waves Bluetooth Low Energy IP provides Balletto MCUs with the robust connectivity at ultra-low power consumption, and supports Bluetooth LE Audio and Auracast broadcast audio, for customers who wish to leverage Balletto to create highly differentiated wireless audio products. The Balletto family also relies on Ceva-Waves 802.15.4 IP for Thread, Zigbee and Matter support in smart home applications.

“Our Balletto family of connected, intelligent MCUs are tailored to meet the growing demand for AI/ML workloads in battery-powered devices,” said Mark Rootz, VP Marketing at Alif Semiconductor. “Ceva’s Bluetooth Low Energy and 802.15.4 IPs provide us with a highly-proven and robust connectivity solution for our chip design, allowing us to focus our R&D resources on differentiating our MCU to deliver outstanding performance for the most demanding wireless audio and smart home AI/ML use cases.”

“Wireless connectivity is a fundamental requirement of every intelligent device, and we’re proud to be the trusted supplier of embedded wireless IP to industry leaders and innovators alike, including Alif Semiconductor,” said Tal Shalev, Vice President and General Manager, Wireless IoT Business Unit at Ceva. “Our Bluetooth Low Energy IP has powered billions of devices to date, and we’re excited to partner with Alif to enable their Balletto family of intelligent MCUs with robust connectivity and high-bit rate audio.”

The Ceva-Waves Bluetooth IP platforms provide comprehensive solutions for both Bluetooth LE and Bluetooth dual mode connectivity, spanning RF, Modem, Baseband Controller, and complete Host and Profile software stacks. All the latest features of Bluetooth are supported, including AoA / AoD / Direction Finding, LE Audio / Auracast, Periodic Advertising with Response, and other enhancements such as Channel Sounding. It also comprises an IEEE 802.15.4 addon for Thread, Zigbee and Matter support. With more than 4.5 billion devices shipped to date and dozens of licensees, the Ceva-Waves Bluetooth IP is widely deployed in consumer, automotive, industrial, medical and IoT devices with many of the world’s leading semiconductors companies and OEMs, including smartphones, tablets, beacons, wireless speakers, wireless headsets and earbuds, hearing aids and other wearables.

The Ceva-Waves Bluetooth IP is part of the Ceva-Waves unique and broad family of wireless connectivity IP platforms that also includes the Ceva-Waves Wi-Fi, UWB, NB-IoT and Links multi-protocol platforms.