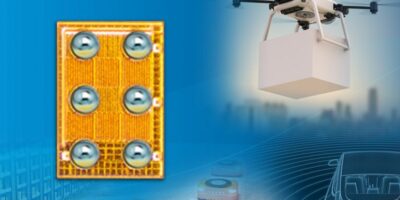

The latest generation of transient voltage suppression (TVS) diodes from STMicroelectronics deliver higher protection in smaller packages, says the company.

The TVS diodes are claimed to deliver market-leading power density, handling 600W and 1500W transient power in SMB Flat, and 400W and 600W in SMA Flat packages that have a low profile of just 1.0mm.

In addition to the lower profile, ST’s 1500W SMB Flat package has transient-power capability equivalent to that of conventional devices in SMC packages, in a footprint more than 50 per cent smaller. The 400W and 600W SMA Flat and SMB Flat devices are footprint-compatible with alternatives in conventional SMA and SMB packages, adds ST. Leakage current is five times lower compared with other TVS diodes on the market, to minimise the impact on system operation and power consumption.

The low-profile, high-power protection diodes cover a range of standoff voltages from 5.0V to 188V, suitable for use in applications such as telecomms equipment, e-bikes, drones, robots, automotive electronics, consumer products and power tools.

Industrial-grade and AEC-Q101 automotive-qualified parts are available.

The 400W and 600W devices are in production now, 1500W diodes are available in sample quantities and will enter production in early 2020.

All packages feature wettable flanks that facilitate automatic optical inspection (AOI) for production quality control.