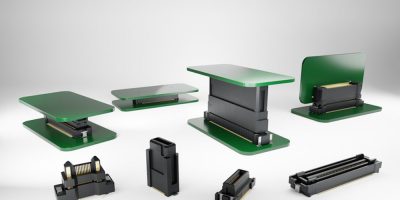

Harwin launches floating connectors to support high-speed automated manufacture and reliability

Harwin has launched a range of board-to-board connectors that address the data and power transfer demands of high-performance applications while accommodating small movements in multiple axes to support high-speed automated assembly and enhance resistance to shock and vibration during operational life.

Offering up to 160 contacts in a symmetrical double row layout, the new Flecto floating connector family is available with three choices of miniature pitches: 0.5mm (.0197”), 0.635mm (.025”) and 0.8mm (0.0315”). By accommodating movement of up to ±0.5 mm in both the X and Y axes, Flecto allows for accurate placement of multiple connectors between the same two PCBs where the sum of misalignments might, otherwise, present challenges for high-speed, high-precision mating.

The positional tolerance flexibility of Flecto connectors also enhances system reliability by maintaining connection integrity during shock and vibration events and reducing the possibility of degradation or failure from ‘fretting’ – a situation that occurs when long-term vibration causes plating to wear from rigid mating pins, exposing the underlying alloy to potential oxidation.

Flecto connectors support board-to-board mating heights as low as 7.2mm and data rates as high as 12Gbit/s. Additional power pins available with the 0.5mm pitch options are rated for currents up to 3A. Vertical and horizontal female connectors allow boards to be connected in parallel or at right angles to each other, while Flecto signal-only connectors feature either location pegs or posts to eliminate movement during solder reflow. On the mixed signal and power connectors, through-board solderable posts are provided for location accuracy and enhanced mechanical strength. A number of the connectors feature shrouded contacts to prevent accidental damage when no mating connector is present, while others offer polarisation within the shroud to ensure uni-directional mating.

Target applications for the new range include factory automation, electric vehicles, LED displays, security cameras, IoT devices, data communications and a wide variety of embedded systems.

Written by Annie Shinn