GaN FETs perform for e-bikes, drones and robotics, says EPC

Introducing the EPC9167 GaN-based inverter reference design, Efficient Power Conversion (EPC) said that the FET enhances motor system performance, range, precision and torque, while lowering overall system cost.

The three-phase brushless DC (BLDC) motor drive inverter uses the EPC2065 eGaN FET. The EPC9167 operates from an input supply voltage between 14 and 60V (nominal 48V) and is available in two configurations – a standard unit and a high current version.

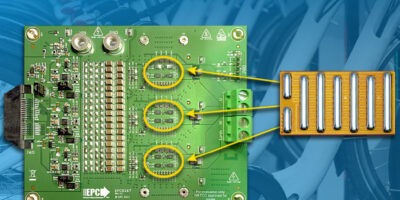

The EPC9167 standard reference design board is a three-phase BLDC motor drive inverter board featuring the EPC2065 eGaN FET rated at 3.6 mOhm maximum RDS(on), 80V maximum device voltage. This standard configuration uses single FETs for each switch position and can deliver up to 20A RMS maximum output current.

For the high current configuration, the EPC9167HC, reference design uses two paralleled FETs per switch position with the ability to deliver up to 42Apk (30A RMS) maximum output current.

Both versions contain all the necessary critical function circuits to support a complete motor drive inverter including gate drivers, regulated auxiliary power rails for housekeeping supplies, voltage, and temperature sense, accurate current sense, and protection functions. The boards feature the ST Microelectronics’ STDRIVEG600, smart motor drive GaN half-bridge driver.

The EPC9167 boards measure just 130 x 100mm (including the connector). The boards can also be configured for multi-phase DC/DC conversion and support both phase and leg shunt current sensing. The boards demonstrate benefits of a GaN-based motor drive, for example lower distortion for lower acoustic noise, lower current ripple for reduced magnetic loss, lower torque ripple for improved precision, and lower filtering for lower cost.

The EPC9167 boards’ low weight and small size enable them to be integrated into the drive into the motor housing and support low inductance, higher power density motors.

EPC provides full demonstration kits, which include interface boards that connect the inverter board to the controller board development tool for fast prototyping.

The default setting for the GaN-based motor drive kit is 100kHz switching frequency and 14 ns deadtime. The kit is designed to be programmed for different frequencies and deadtimes, although operation at around 100kHz eliminates the need for electrolytic capacitors and allows the use of lower capacitance. It also reduces motor losses, said EPC. The company also advised operating the boards with very small low deadtime of around 14 ns to allow higher torque per Ampere. Combined these features improve inverter and motor system efficiency by more than seven per cent compared with a silicon MOSFET, which typically operates at 20kHz and 500 ns deadtime, said EPC.

The EPC9167 and the EPC9167HC reference design are available for immediate delivery from Digi-Key.