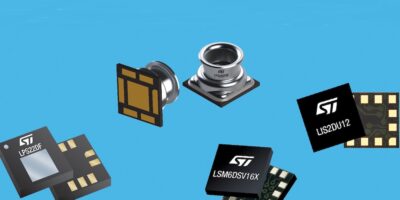

A third generation of MEMS sensors are intended for consumer mobiles and smart industries, healthcare, and retail.

MEMS technology drives the intuitive context-aware features of today’s smartphones and wearables. STMicroelectronics claims that its latest generation of MEMS sensors take performance beyond established technical limitations on output accuracy and power consumption. The new sensors can deliver the highest accuracy for product features such as activity detection, indoor navigation, and precision industrial sensing. At the same time, they keep battery demand low for longer runtimes.

Selected variants include extra features such as ST’s machine learning core (MLC) and electrostatic sensing. The MLC brings adaptive, machine learning capabilities to edge applications that operate at extremely low power. The charge variation (QVAR) sensing channel monitors changes in electrostatic charge, either through contact with the body in a smartwatch or fitness band or by non-contact sensing (radar). The MEMS sensors with QVAR can enhance user interface controls for seamless interactions or to simplify detection of moisture and condensation. Radar mode applications include human presence detection, activity monitoring and people counting.

The LPS22DF and waterproof LPS28DFW barometric pressure sensors operate from 1.7 microA and have absolute pressure accuracy of 0.5hPa. The LPS28DFW has dual full scale capability, enabling accurate vertical position both underwater and out of water. The full scale range is selectable up to 1260 or 4060hPa, equivalent to water pressure at a depth of about 98 feet (30m). The sensors enhance altimeter and barometer performance in portable devices and wearables including sport watches. Typical industrial applications include equipment for weather monitoring and accurate water-depth sensing.

The LIS2DU12 three-axis accelerometer has been designed to build a low power architecture with active anti-aliasing. The anti-aliasing filter operates with a current consumption among the lowest in the market, claims STMicroelectronics. The LIS2DU12 consumes only 3.5 microA at 100Hz output data rate (ODR) and is also the first accelerometer with I3C interface, according to the company.

The accelerometer is a small footprint of 2.0 x 2.0 x 0.74mm. The accelerometer is designed for wearable devices, hearing aids, true wireless stereo (TWS) and wireless sensor nodes.

The LSM6DSV16X six-axis iNEMO inertial module contains QVAR electrostatic sensing as well as the MLC and a finite state machine (FSM). The operating current can be as little as 12 microA. The FSM enables adaptive self-configuration (ASC). With ASC, the device understands the context and reconfigures itself without waking up the system, gaining a significant extra power saving.

The MEMS sensor will enter production and has been demonstrated in an electrostatic radar application for early user detection to accelerate waking-up a laptop PC.

The LPS22DF pressure sensor is supplied in a 2.0 x 2.0 x 0.73mm 10-lead LGA package and the LPS28DFW is supplied in a 2.8 x 2.8 x 1.95mm seven-lead LGA are in production now. Free samples are available. The LIS2DU12 and LSM6DSV16X are scheduled for production later in 2022.