Anritsu has collaborated with Qualcomm to deliver what is believed to be the first enhanced network slicing and user equipment (UE) power saving protocol conformance tests for 5G new radio (NR) standalone (SA). The equipment is verified on the 5G NR mobile device test platform ME7834NR powered by Qualcomm’s Snapdragon X65 5G Modem-RF System, which the company says is the world’s first Release 16 modem-RF system.

Network slicing enables support of specific use cases on a set of network resources dynamically configured for the purpose. Third Generation Partnership Project (3GPP) Release 16 introduces support for interworking from evolved packet core (EPC) to 5G core (5GC) for network slices. It also introduces authentication and authorisation controls.

New features for power saving in user equipment is also defined in 3GPP Release 16. These include wake up signal, enhanced cross-slot scheduling, adaptive MIMO (multiple input multiple output) layer reduction and relaxed radio resource management measurement.

The conformance tests are defined by 3GPP in TS 38.523-1 corresponding to core requirements in TS 38.331and have been submitted to 3GPP Radio Access Network Working Group 5 (RAN WG5) by Anritsu. These tests will also be submitted to Global Certification Forum (GCF) Certification Agreement Group (CAG), and PCS Type Certification Review Board (PTCRB) PTCRB Validation Group (PVG) for approval in the upcoming meetings.

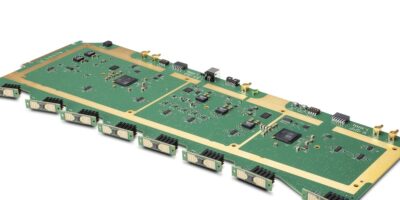

The proposal consists of the 5G NR mobile device test platform ME7834NR, which is registered with both the GCF and PTCRB as Test Platform 251.

The ME7834NR is for 3GPP-based protocol conformance test (PCT) and carrier acceptance testing (CAT) of mobile devices incorporating multiple radio access technologies. It supports 5G NR in both standalone and non-standalone in addition to LTE, LTE-Advanced, LTE-A Pro, and W-CDMA. Combined with Anritsu’s over the air (OTA) RF chamber MA8171A and RF converters, the ME7834NR covers the sub-6GHz and millimeter wave (mmWave) 5G NR frequency bands.