NXP Semiconductors have unveiled its new S32R47 imaging radar processors in 16 nm FinFET technology, building on NXP’s proven expertise in the imaging radar space. The third generation of imaging radar processors delivers up to twice the processing power versus the previous generation, alongside improved system cost and power efficiency. In combination with NXP’s mmWave radar transceivers, power management and in-vehicle networking solutions, the S32R47 family meets functional safety ASIL ISO 26262 ASIL B(D) requirements and prepares the automotive industry for new levels of autonomous driving.

According to Yole Intelligence’s Status of the Radar Industry 2024 report, by 2029, approximately 40% of vehicles entering the road will be passenger cars with driving automation Level 2+(L2+)/ Level 3 (L3) as well as an increasing number of vehicles with Level 4 (L4). To serve the fast-growing autonomous driving market for SDVs, automotive OEMs and tier 1 suppliers need to improve radar performance as it is essential for safe, advanced autonomy features such as piloted driving or fully automated parking.

“The S32R47 can efficiently process three times, or more, antenna channels in real time than today’s production solutions. It enables improved imaging radar resolution, sensitivity and dynamic range – required by demanding autonomous driving use cases – while still meeting the stringent power and system cost targets set by OEMs for volume production,” said Meindert van den Beld, Senior Vice President & General Manager, Radar & ADAS.

Imaging radar leverages richer point cloud data for more detailed modelling of the environment. This is a key enabler for AI based perception systems which allow for assisted and autonomous driving in the most challenging environmental conditions, such as complex urban scenarios.

The S32R47 integrates a high-performance multi-core radar processing system, allowing denser point cloud output and enhanced algorithms that enable next-generation ADAS systems. This results in better separability of objects, improved detection reliability and more accurate classification of objects such as vulnerable road users or lost cargo.

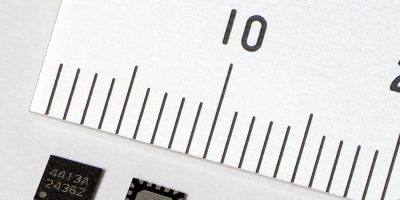

The new solution delivers up to 2x processing performance in the radar MPU in a 38% smaller IC footprint. It also includes AI/ML support for features like enhanced Direction of Arrival (DoA) processing and object classification.