Smart home technology has expanded rapidly in recent years. A growing number of households are adopting smart speakers like Amazon Echo and Google Home. Companies that once made simple home appliances now have a demand for high-fidelity audio output. This audio goes beyond the typical beep or tone announcing that the laundry is done; this type of audio technology enables a fridge to read a grocery list aloud, or have a light switch remind someone to turn off the lights before leaving the room.

Adding advanced audio features can be daunting, adding complexities to an engineering team’s already constrained design timeline. In this post, I’ll discuss four challenges related to smart home audio design and how to simplify the process.

1. Project requirements are difficult to define.

The project you’re working on sounds simple enough: make this appliance talk. But many design choices and challenges accompany audio output, and it can be difficult to choose the right amplifier among a sea of options that at first glance all seem very similar.

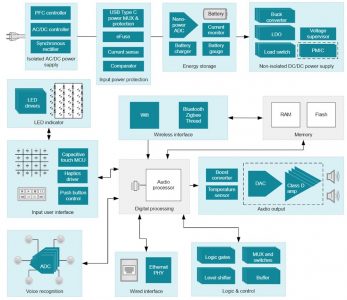

To simplify the amplifier selection process, TI’s interactive block diagrams provide component recommendations for specific smart home applications. For example, the smart speaker block diagram shown in Figure 1 highlights the audio subsystem and various speaker amplifiers with features that address a variety of smart home design requirements. Audio reference designs on the same page provide schematics and companion parts that you can use as a template for your project, increasing system-level knowledge and reducing component selection woes.

Figure 1: Smart speaker block diagram

TI block diagrams are a great first step for starting a design, but the selection of a speaker amplifier will ultimately come down to your project requirements. Two of the most common requirements in smart home products are high efficiency and sleek device profiles.

2. Audio output and advanced features decrease energy efficiency.

Adding extra functionality to a smart home device increases power consumption, and audio is no exception. As tech companies strive to go green and governments add regulations on standby power, it’s become more important to optimize the next generation of products for low power consumption. Inefficient audio systems contribute heavily to wasted power and decrease user satisfaction by raising electricity bills, depleting batteries faster and even making devices hot to the touch.

Audio amplifiers are not always playing, but they must be responsive when users need feedback or a notification; think of a security camera or a smart display in idle mode. On the other hand, a Bluetooth® speaker blasting a summer playlist needs to play music efficiently so that its battery (and the pool party) can last all day.

There are two main aspects of power consumption in audio: efficiency during play and idle mode. A Bluetooth® speaker blasting a summer playlist needs to play music efficiently so that its battery (and the pool party) can last all day. Whereas, a smart display waiting for a voice-command should not consume an excessive amount of power if it’s not playing audio.

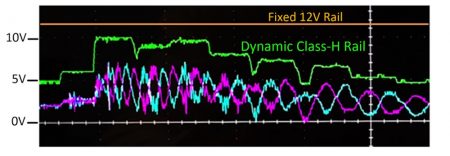

To address diverse applications around the smart home, TI’s latest speaker amplifiers have advanced power-management features built in. A proprietary Hybrid Modulation scheme minimizes idle current losses in >12-V systems. An integrated Class-H control of the supply rail can extend runtime by 50% in battery-powered systems. Figure 2 shows how a Class-H solution dynamically changes the supply rail to reduce power losses.

Figure 2: A dynamic supply rail saves significant power over a fixed rail

Using a device with an integrated boost and Class-H control can save space, overall bill-of-material cost, and power consumption while supporting look-ahead to prevent audio clipping. For applications above 12V, an amplifier with integrated Class-H control and an external boost can still provide significant power savings and look-ahead to prevent clipping. Both solutions save demand on the host processor and reduce software development through integration.

3. Physical constraints limit audio performance.

Electronics are shrinking into sleek, minimalistic designs. The limited form factor in home appliances that were never designed for audio makes it difficult to add extra components such as amplifiers, digital signal processors (DSPs), boost converters and speakers without compromising the overall solution size.

With these constraints in mind, TI’s audio teams have focused on creating amplifiers that integrate more features to reduce external components and optimize the audio subsystem’s footprint.

In a smart speaker that is the center of the smart home ecosystem, high-quality music and virtual assistant feedback are crucial to user satisfaction. Adding an audio DSP to produce high-quality output typically adds cost and increases the printed circuit board (PCB) footprint. TI offers audio amplifiers with integrated processing, enabling speaker tuning to output the clearest virtual assistant response and richest music experience. An external echo-cancellation algorithm can even use the post-processed signal to help a smart speaker more accurately distinguish between audio output and user voice commands.

Electromagnetic interference (EMI) is caused by the high switching frequency of Class-D speaker amplifiers, which adds distortion to an audio signal. This is usually suppressed by several large inductors, but features like spread spectrum and phase optimization suppress EMI without the need for large external inductors, and save both space and cost while producing audio output with ultra-low distortion.

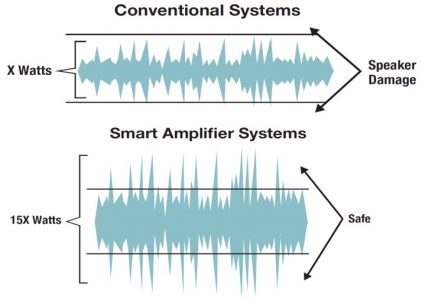

Typically, a speaker’s output power is closely related to its size; if you want louder sound, you’ll need a bigger transducer, which isn’t always an option when designing a space-constrained product. A video doorbell needs to output a homeowner’s voice loud and clear, even in noisy environments, while maintaining a slim profile. Small speakers that fit in these designs tend to output lower power and are more easily damaged by overheating or over excursion. Thanks to TI speaker protection algorithms, smaller speakers can safely output higher volume and better quality than ever before. Hear the difference in this Smart Amp A/B experiment.

As pictured in Figure 3, TI Smart Amps allow engineers to take full advantage of a speaker’s capabilities and output higher average power without compromising the integrity of the transducer. Therefore, in a noisy environment, the increased output means a user can more easily hear from a video doorbell or a smart display. Clear communication is critical in these applications and the two-way audio reference design utilizing TI Smart Amplifiers can help lay the foundation for a successful project.

Figure 3: Speaker protection amplifiers enable speakers to output twice the loudness as traditional amplifiers without damaging them

In addition to loudness, thermal dissipation is an important design consideration. Heat dissipates poorly in small form factors, posing a problem for ever-shrinking smart home products. Heat damages internal components and creates a poor user experience. Designing with thermal energy in mind means considering PCB layout and copper thickness or implementing features like thermal foldback, which enables speaker amplifiers to reduce heat by adjusting the gain on audio signals on the fly in the event of overheating. Keeping thermal management in mind from the beginning leads to safe and reliable products.

4. Advanced audio amplifier technologies/features require deep expertise and are difficult to implement.

Advanced features solve many problems and sound great on paper, but often are too difficult to implement. To simplify the design of next-generation products, TI has not only integrated advanced features into our amplifiers, but made them easily controllable through a free software tool.

The PurePath™ Console 3 software suite is an easy-to-use graphical user interface that simplifies working with these devices. Using the software, engineers can quickly tune audio output, calibrate settings and characterize speakers. Step-by-step tuning and characterization wizards as well as a library of training resources lower the learning curve associated with using new tools.

Power management, speaker protection and audio equalization are integrated in some TI Audio devices and are easily configurable through PurePath™ Console 3, requiring little to no extra software development effort. This makes it possible to create a power-efficient, high-fidelity audio subsystem that improves user satisfaction with low risk to your overall project timeline.

Additional resources

- • Check out the smart home audio portfolio.

- • Explore where audio is being added in the smart home.