Claimed to offer more robust performance than existing absolute encoders and better resolution and accuracy than traditional Hall effect sensors for industrial robotics and other demanding applications, the RAMK060 is a rotational absolute magnetic kit encoder from Vishay Intertechnology.

The high precision position sensor uses contactless technology to achieve above 13-bit accuracy, 19-bit resolution, and above 16-bit repeatability, reports Vishay, while maintaining robustness against external magnetic fields, moisture, airborne pollution, vibration, mechanical shock, and changes in temperature. It also has a useful electrical angle of 360 degrees and operates over a temperature range of -40 to +85 degrees C. Higher maximum temperature models are available on request.

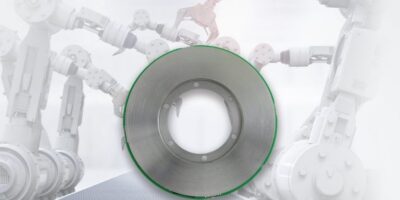

According to Vishay, it is suitable for space-constrained applications, due to the rotor and stator kit design, the off-axis design (for hollow shaft mounting), the slim profile of around 6.5mm and weighing less than 55g.

The RAMK060 has an outside diameter of 60mm and inner diameter of 25mm. Several multi-turn variants are available, including connection to a backup battery when system power is off. SPI, SSI, or Biss-C output signals are available.

The RAMK060 is self-calibrating, to compensate for mechanical misalignment

Vishay’s patented design is particularly suited for applications that demand precise and repetitive motion such as arm joints for industrial robots and collaborative robots, steering wheels for automated guided vehicles; and machine tools used in printing, textile manufacturing, and milling.

Samples and production quantities of the RAMK060 are available now, with a lead time of 16 weeks for larger orders.

http://www.vishay.com