For the smart factory, Axiomtek offers the IMB525R ATX industrial motherboard which is versatile and offers superior graphics performance, says the company.

The IMB525R server-grade ATX motherboard is powered by the Intel Xeon® E, 9th/8th generation Intel Core, Intel Pentium or Intel Celeron processors with the Intel C246 chipset. According to Axiomtek it is flexible with I/O expandability and supports error correcting code (ECC) memory which provides improved data integrity and system reliability through automatic data correction.

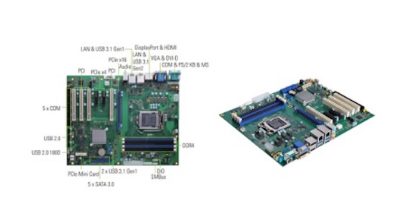

The IMB525R is specifically suited for industrial workstations, embedded networks, factory automation, robotic motion control, machine vision, and testing and measurement. It has five SATA-600 ports with software RAID 0/1/5/10 for reliable data storage and protection and four 288-pin DDR4-2666/2400 ECC DIMM slots with a maximum memory capacity of 128Gbyte. In addition, it can be expanded with one PCIe x16 slot, two PCIe x4 slots, four PCI slots and one PCI Express Mini Card slot, according to customer requirements.

It also supports Trusted Platform Module 2.0 (TPM 2.0) to enhance network security whether as a cloud server, data centre or for industrial IoT (IIoT) applications. The Intel Coffee Lake Refresh-based ATX motherboard is designed to reduce overall development cost and speed up time-to-market, adds Axiomtek. There is also a watchdog timer and hardware monitoring functions.

The IMB525R is integrated with the Intel UHD Graphics 630 for visual performance, enabling triple simultaneous displays via DisplayPort++, HDMI, DVI-D, and VGA for multi-display applications. There are two USB 3.1 Gen 2 ports, four USB 3.1 Gen 1 ports and seven 180D type A USB 2.0 ports and four RS-232, two RS-232/422/485, two Gigabit LANs with Intel Ethernet controller I211-AT and Intel Ethernet connection I219-LM, eight-channel digital I/O, one HD Codec audio, one SMBus, and one PS/2 keyboard and mouse.

Operating temperature ranges from 0 to +60 degrees C for use in harsh environments.

http://www.axiomtek.com