At this week’s GPU Technology Conference in San Jose, California this week, Nvidia has announced an artificial intelligence (AI) computer that makes it possible to create millions of intelligent systems.

There are two versions of the Nvidia CUDA-X Jetson Nano computer, a $99 development kit for developers and makers, and a production-ready module, priced at $129 for companies to create mass-market edge systems.

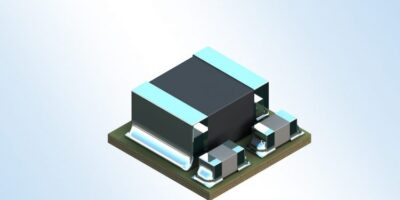

The small CUDA-X AI computer delivers 472GFLOPS of compute performance for running modern AI workloads and is power-efficient, consuming as little as 5W.

Jetson Nano supports high-resolution sensors, can process many sensors in parallel and can run multiple modern neural networks on each sensor stream. It also supports many popular AI frameworks, allowing developers to integrate preferred models and frameworks.

The Jetson Nano developer kit is priced to bring the power of modern AI to a low-cost platform, for makers, inventors, developers and students to build AI projects, for example mobile robots and drones, digital assistants and automated appliances.

The kit includes support for full desktop Linux and is compatible with many popular peripherals and accessories. Ready-to-use projects and tutorials are included to help makers get started with AI fast.

The Jetson Nano module can be used in embedded applications, including network video recorders, home robots and intelligent gateways with full analytics capabilities.

The design includes power management, clocking, memory and fully accessible input/outputs. The AI workloads are entirely software defined, allowing companies to update performance and capabilities even after the system has been deployed.

To help customers easily move AI and machine learning (ML) workloads to the edge, Nvidia has worked with Amazon Web Services (AWS) to qualify AWS Internet of Things Greengrass to run optimally with Jetson-powered devices such as Jetson Nano.

Nvidia CUDA-X is made up of over 40 acceleration libraries for graphics processing unit (GPU) -accelerated computing. JetPack SDK is built on CUDA-X and is a complete AI software stack with accelerated libraries for deep learning, computer vision, computer graphics and multimedia processing that supports all of the Nvidia Jetson family, including Jetson AGX Xavier for fully autonomous machines and Jetson TX2 for AI at the edge.

JetPack includes the latest versions of CUDA, cuDNN, TensorRT and a full desktop Linux OS.

A reference platform has also be created to minimise the time spent on initial hardware assembly.