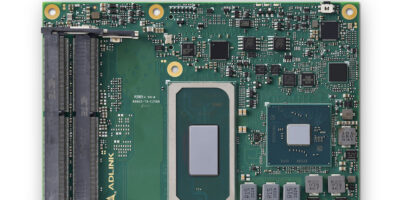

Claimed to be the first COM Express Type 6 module to support PCI Express Gen 4 x16, the Express-TL effectively doubles the bandwidth of previous COM Express modules, says Adlink.

The Express-TL module with 11th Generation Intel processors is designed rugged operating temperatures, across the -40 to +85 degrees C range in embedded and industrial applications. It can operate 24/7 in industrial settings with 10-year availability, adds the company.

In addition to Intel Core, Xeon W and Celeron 6000 processors and octa-core performance, the module has Intel UHD Graphics and Intel AVX-512 VNNI to provide artificial intelligence (AI) inferencing. The Express-TL can be used for demanding applications such as image processing and analysis, high speed video encoding and streaming, medical ultrasound and predictive traffic analysis.

The Intel UHD Graphics core supports four 4K independent displays, including high definition multimedia interface (HDMI), DisplayPort (DP), LVDS, embedded DisplayPort (eDP) and legacy VGA displays.

The Express-TL module provides 2.5Gbit Ethernet and four USB 3.2 Gen 2 ports, allowing transfer rates above 10Gbits per second.

Intel Time Coordinated Computing (TCC), combined with time-sensitive networking (TSN) Ethernet controller is used in industry 4.0 applications for intelligent, agile and increasingly autonomous operation.

Adlink reports an additional eight degrees C at 25W TDP with ECC memory feature and on-board NVMe storage make the Express-TL module suitable for space constrained applications

AI, machine learning and IoT devices increase demand for real-time processing from the edge to the cloud. The Express-TL module offers advanced tuning controls, immersive graphics, and connectivity for AI, workload consolidation, and other intensive computing demands, added the company.

The Express-TL COM Express Type 6 module helps shorten development cycles and reduce costs, with vibration resistance, wide operating temperature range and reliable system performance.

Adlink plays a role in developing open standards such as the COM Express specification. Adlink has held leadership positions in the PCI Industrial Computer Manufacturers Group (PICMG) which is responsible for many widely accepted standard form factors in the embedded industry.

Adlink Technology manufactures edge hardware and develops edge software for embedded, distributed and intelligent computing ranging from powering medical PCs in the intensive care unit to building the world’s first high-speed autonomous race car.

Adlink contributes to open source, robotics, autonomous, IoT and 5G standards initiatives across more than 24 consortia, driving innovation in manufacturing, telecommunications, healthcare, energy, defence, transportation and infotainment.