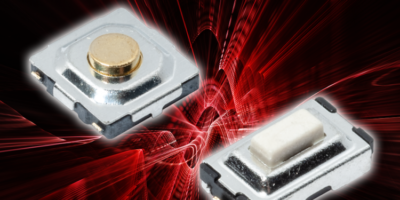

Two sub-miniature tact switches, the PTS636 and PTS526, save PCB space for design engineers developing home automation and IoT electronic devices, says C&K.

The space savings electronics designers to add other components on the PCB. The PTS636 switch has a 6.0 x 3.5mm footprint and an adjustable thickness of 2.5, 4.3 and 5.0mm; the PTS526 has a footprint of 5.2 x 5.2mm and an adjustable thickness of 0.8 to 2.0mm. Both offer a large actuation surface for easier integration, for applications such as home automation, IoT devices and e-cigarettes, as well as control systems for items such as drones, e-bikes and robot vacuum cleaners.

The PTS526 and PTS636 switches are manufactured in surface mount technology. The PTS636 is additionally made in through hole format. Both use a hard actuator, ensuring that it can be fully integrated into standard processes, with no need for an additional interface button. This functionality reduces time and costs for an end equipment manufacturer, points out C&K. The switches provide optimum performance and retains high reliability up to 500,000 cycles.

The PTS636 design includes a 2.5mm height version with integrated ground pin and the PTS 526 design includes a version with an integrated ground pin. There is ESD protection soldered to the PCB for routing unwanted electrical overload.

The PTS 636 is available in four different operating-force levels 130, 180, 250 and 320gf. There are three actuation forces for the PTS 526: 160, 260 and 320gf. Both sets of switches are rated at 50mA, have a bounce time of less than 10ms and an operating temperature range of -20 to +70 degrees C.

C&K was founded in 1928 and manufactures electromechanical switches. It has more than 55,000 standard products and 8.5 million switch combinations for use in automotive, industrial, IoT, wearables, medical, telecomms, consumer products, aerospace and point of sale (POS) terminals.

C&K products include tactile, pushbutton, snap-acting, toggle, rocker, detect, DIP, keyswitch, navigation, rotary, slide, switchlock, thumbwheel, smart card readers, high-rel connectors and custom assemblies.