Sensing to cover all radar segments from Europe’s NCAP (New Car Assessment Programme) to 4D imaging radar is provided by a suite of automotive radar sensor chipset suite by NXP.

The NXP radar sensors are built on 16nm FinFET and 40nm RFCMOS technology. The include the RFCMOS 77GHz radar transceivers, the S32R45 high-performance radar processors for imaging radar and the S32R294 radar processor for corner and front radar applications

The processors and transceivers offer automotive manufacturers flexible and scalable configurations that address NCAP requirements for corner and front radar applications as well as what is claimed to be the first commercially viable path to volume production for 4D imaging radar.

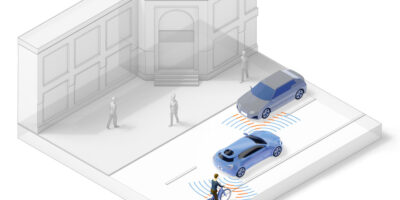

4D imaging radar expands radar’s capabilities from measuring range and speed to include direction, angle of arrival, and elevation measurement.

NXP offers imaging radar, which “significantly enhances radar’s performance”. It delivers multi-modal capabilities and extends today’s L2+ features, such as highway pilot and lane change assistance, by offering very high resolution images for precise environmental mapping and scene understanding. This is an important part of enabling full autonomy in urban settings, says NXP.

NXP’s new purpose-built S32R45 radar processor and the TEF82xx transceivers deliver the fine angular resolution, processing power and range required to distinguish between small objects in the distance and separate and classify vehicles and vulnerable road users (e.g. cyclists or pedestrians) in crowded environments. This capability is targeted at providing better driving decisions.

The suite also provides scalability for long-range front radar and advanced multi-mode use cases, e.g. simultaneous blind-spot detection, lane change assistance and elevation sensing. These advanced applications require extended range and significantly enhanced angular resolution to detect and separate multiple objects simultaneously. The new S32R294 radar processors, combined with the NXP TEF82xx transceivers provide a scalable solution to address NCAP, advanced corner radar and long-range front radar sensor requirements. They can also be tailored for individual use cases.

“Radar has evolved from just detecting other cars’ velocity and distance to providing imaging radar’s high-resolution object and feature detection for precisely mapping the car’s surroundings,” said Torsten Lehmann, executive vice president and general manager, Radio Frequency Processing, NXP.

NXP claims to be the first company to broadly deliver 77GHz RFCMOS radar technology in high volume, mass production and says it helps customers optimise the total cost of ownership with scalable, re-useable radar systems.

Target applications are in traditional automotive manufacturers, focused on automated driving levels one to three, and for mobility as service innovators developing robotaxi and safe delivery applications for levels four and five automation.

The devices are sampling now, with mass production expected in 2021.