Linear current regulators from STMicroelectronics provide dynamic automotive lighting control using the CAN FD Light protocol. The driver is intended for use with OLED lamps for bright, homogeneous and high contrast lighting from a small surface area.

The L99LDLH32 has 32 regulated current sources, independently programmable from 1.0 to 15mA. The regulator can drive individual pixels in external and interior lighting applications. Global dimming is also provided, with eight-bit resolution. The driver is powered at the vehicle battery voltage and produces outputs of up to 35V to cover a wide emitter forward voltage spread.

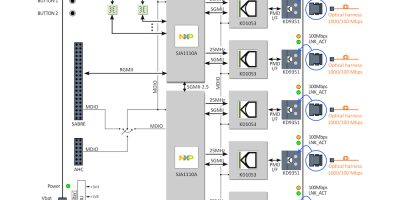

The integrated CAN FD Light protocol handler and transceiver simplify connection to the vehicle’s communication infrastructure and controlling domain ECU (electronic control unit). CAN FD Light’s synchronised commander / responder communication is engineered for controlling simple devices such as lights and sensors. According to ST, this saves costly external components such as timing crystals.

The data bandwidth of 1Mbit per second enables designers to create complex animated light patterns and permits smoothly modulated transitions and dimming.

On-chip memory cells allow programming of parameters, such as current level and PWM dimming for standalone operation, to provide a failsafe mode in the event of the communication bus or controller malfunction.

The L99LDLH32’s features for functional safety include a fault-status pin, voltage and temperature monitors, a programmable timeout watchdog, short-circuit and open-load detection. In addition, frequency dithering minimises electromagnetic emissions.

Consequently, target applications include safety critical lighting such as taillights, stoplights, and turn indicators.

The driver is monolithically integrated using ST’s BCD9sL process. It is AEC-Q100 qualified and packaged in a 7.0 x 7.0mm QFN48 device with wettable flanks and an exposed thermal pad to aid dissipation