Claimed to offer unparalleled performance-power benefits, the PCIe Gen4 NVMe solid state drive (SSD) controller is designed for edge computing and cloud data centre applications.

The SSD controllers are designed to meet the need for lower power and higher performance in next-generation data centres and edge devices as artificial intelligence (AI) and 5G gain momentum, explains Marvell Semiconductor. The SSD controller is claimed to be the industry’s lowest power PCIe Gen4 NVMe solid state drive (SSD) controller, leveraging the company’s system-on-chip (SoC) design expertise and storage IP distributed data.

Nigel Alvares, vice president of marketing for the flash business unit at Marvell Semiconductor, believes the PCIe Gen4 NVMe SSD controllers are “demonstrating Marvell’s leadership in storage, delivering the industry’s first four-channel PCIe Gen4 NVMe SSD controllers with the industry’s lowest power consumption that will help revolutionise SSD solutions for the data economy.”

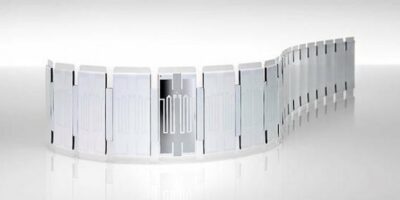

The 88SS1321, 88SS1322 and 88SS1323 are believed to be the industry’s first PCIe Gen4 DRAM and DRAM-less SSD controllers to be fabricated on a 12nm process. With support covering all existing and emerging m.2 (22110 to 2230), BGA, EDSFF and U.2 SSD form factors, the controller family is suitable for cloud data centre server compute storage, enterprise boot drives, PC client storage and gaming storage as well as emerging industrial and edge device applications.

The PCIe Gen4 NVMe SSD controllers will enable next-generation 3D and QLC NAND devices that maximise cost efficiency and reduce total cost of ownership, adds Marvell. The compact, DRAM-less controller architecture allows for a stand-alone SSD controller and NAND unit to be mounted side-by-side on a single-sided, compact m.2230 form factor SSD. The resulting space saving leaves more room to house battery packs compared with m.2280 SSDs and also provides better performance compared to PCIe Gen 3×4 SSDs and lower power consumption compared to eight NAND channel controller-based SSDs, says Marvell.

Marvell’s revolutionary SSD controllers are available for sampling today.