Rain radio frequency identification (RFID) inlays can be used on metal surfaces for and have a reading range of 6m.

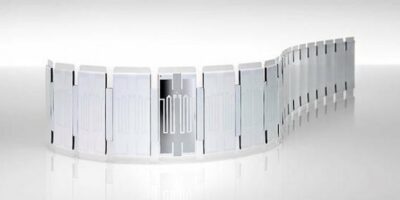

The Skyline Rain RFID inlays and tags have an optimised antenna and spacer-based design. A customised ultra high frequency (UHF) inlay is based on NXP’s UCODE 7xm IC with 448-bit EPC memory and extended user memory of 2kbits. The resulting transponder is then folded and applied around a synthetic spacer developed and provided by identytag of Bad Berleburg, Germany.

The advanced antenna design, the IC’s long read range and reliable operation in dense reader and noisy environments through high interference rejection, as well as optimised spacer material result in an on-metal read range in a compact tag, with a die-cut size of 54 x 25 x 1.8mm.

The inlay is permanently attached to the spacer and a layer of strong and resilient RA-33 adhesive is applied. According to Smartrac, this provides “excellent adhesion” to a range of surfaces. As a finished tag, Skyline’s surface is printable with thermal transfer printers.

The RFID tag can be used for tracking metallic assets, items and components in industrial environments such as automotive, mechanical engineering and aviation. Smartrac’s Skyline inlays and tags comply with VDA recommendations for the automotive industry and supported by the leading automation companies globally.

Smartrac and identytag completed initial product volumes and will be ramping up production in the second half of the year 2019.

Smartrac provides both ready-made and customised products. It makes products smart and enables businesses to digitise, identify, authenticate, track and complement products. Products are used in a wide array of applications such as animal identification, automation, automotive, brand protection, customer experience, industry, library and media management, logistics, retail and supply chain management.

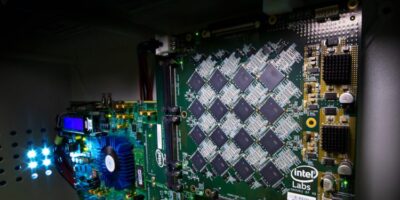

Based in Amsterdam, the Netherlands, Smartac has research and development centres, production and a sales network, complemented by the IoT platform, Smart Cosmos. Smartrac embeds intelligence into physical products for an ecosystem of connected things. The company has also received ARC Quality Certification from Auburn University’s RFID Lab for the design and manufacturing of its RFID inlays.