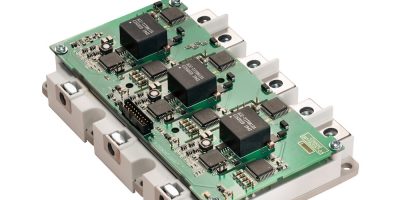

For e-mobility applications, a three-phase SiC MOSFET intelligent power module (IPM) from Cissoid has been designed to improve time to market for electric vehicle (EV) OEMs.

The IPM technology includes a three-phase water-cooled SiC MOSFET module with built-in gate drivers. For OEMs and electric motor manufacturers willing to adopt SiC-based inverters for more efficient and compact motor drives, the IPM is claimed to optimise the electrical, mechanical and thermal design of the power module and its proximity control for automotive and industrial markets.

The first product in this scalable platform, a three-phase 1200V/450A SiC MOSFET IPM, features low conduction losses, with 3.25mOhms on resistance and low switching losses, with 8.3mJ turn-on and 11.2mJ turn-off energies at 600V/300A. It reduces losses by at least a factor three, says Cissoid, compared with the highest performing IGBT power modules. Cissoid’s module is water-cooled through a lightweight AlSiC pin-fin baseplate for a junction-to-fluid thermal resistance of 0.15°C/W. The power module is rated for junction temperature up to +175 degrees C. The IPM withstands isolation voltages up to 3,600V (50Hz, 60 seconds).

The built-in gate driver includes three on-board isolated power supplies (one per phase) delivering each up to 5W allowing it to easily drive the power module up to 25KHz and at ambient temperatures up to +125 degrees C. Peak gate current up to 10A and immunity to high dV/dt (>50KV/µs) enable fast switching of the power module and low switching losses. Protection functions include under-voltage lockout (UVLO), active Miller clamping (AMC), desaturation detection and soft shutdown (SSD).

Dave Hutton, CEO at Cissoid, believes: “With this new SiC intelligent power modules, which is the outcome of years of experience in the development of power modules and gate drivers for extreme temperature and voltage environments, we are happy to deliver our first IPM samples to early SiC adopters and to support the automotive industry in its transition towards highly efficient e-mobility solutions.”