A 42V synchronous buck pre-regulator is combines with a seven-channel power management IC (PMIC) in a power and functional safety solution for systems based on the R-Car V3H SoC for advanced driver assistance systems (ADAS) automotive front cameras and driver monitor cameras.

Renesas has combined the RAA271050 42V synchronous buck pre-regulator that accepts the vehicle’s 12V supply and steps it down to an intermediate supply voltage of 3.3 or 5.0V. The seven channel power RAA271000 PMIC takes the RAA271050’s output and steps it down further to the various supply voltages needed by R-Car V3H and its peripherals such as LPDDR4 memory.

Both devices were developed per the ISO-26262 standard, and can support system safety requirements up to ASIL D. The solution satisfies all the power and functional safety requirements for the R-Car V3H, says Renesas. It provides supply voltages with the current capability to meet all power specifications, including sequence, voltage accuracy, and load step response. It also provides all the necessary power and digital monitoring functions.

According to Renesas the combination provides best-in-class efficiency, with power loss reductions of up to 33 per cent compared to competitive PMICs under comparable operating conditions. Lower power loss enables operation at higher temperatures, reduces cooling costs and improves reliability. The RAA271050 and RAA271000 were designed to match R-Car requirements with no unnecessary overhead, reducing both component cost and PCB area. Reference hardware includes the new components, speeding design time and reducing testing requirements for customers.

The R-CAR V solution includes programmable output voltage, sequencing, I/O configuration and safety configuration. The integrated 12-bit SAR ADC has up to 16 external inputs monitors internal and external signals, eliminating the need for an added system ADC.

Dynamic voltage frequency scaling (DVFS) adjusts output voltage to minimise power consumption and there is optional spread spectrum clocking which mitigates EMI. Support for R-Car V3H SoC activation streamlines the SoC self-test procedures, adds Renesas.

The RAA271050 and RAA271000 are included in an ADAS front camera solution featuring the EagleCam camera module from Lupa-Electronics and Renesas’ R-Car V3H and R-Car V3M SoCs.

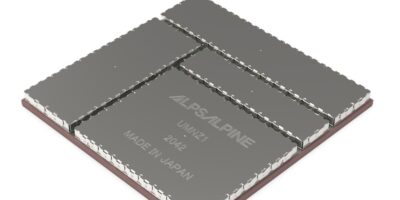

The RAA271050 is offered in a 22-lead, 4.0 x 4.0mm QFN package. The RAA271000 is packaged in a 60-ball FCBGA with 0.8mm pitch. Both devices are sampling today and are expected to be fully available in July 2021.