Multiple protocols can be used on the same network to simplify automation and control networks. According to Adesto Technologies, the FT 6050 smart transceiver’s ability to support LON, LON/IP, BACnet/IP and BACnet MS/TP protocol stacks to “revolutionise field integration for building automation and industrial control applications”.

The FT 6050 smart transceiver system on chip (SoC) enables the popular LON and BACnet industrial protocols to communicate simultaneously over the reliable and widely adopted Free Topology (FT) channel.

Adesto’s FT 6050 smart transceiver allows BACnet workstations and LON network manager and integrator tools to natively field-configure, provision and monitor controllers as either LON or BACnet devices, or both. This enables a flexible architecture and takes advantage of the easy to install, fault tolerant and scalable FT media, points out Adesto. For OEMs, the FT 6050 can enable differentiated architectures with fewer SKUs needed in inventory. It also makes the integrator’s job easier and more flexible for both retrofits and new installations, adds the company.

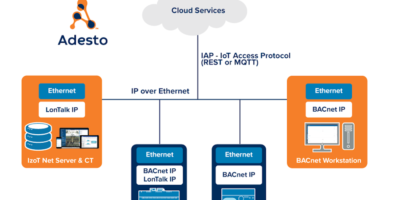

The FT 6050 provides a uniform management architecture that can share data across networks and also externally to cloud systems. Adesto says it will continue to roll out further FT-based innovations across its edge devices and embedded IoT platform, exploiting the ease of interoperability between devices and integration to IoT and cloud systems.”

The FT 6050 smart transceiver SoC is supported in both LON and BACnet configurations by Adesto’s SmartServer IoT, an open and extensible industrial edge server that supports multiple protocols and applications. It enables the convergence of diverse systems into a single edge networking and compute platform.

Enhancements to the FT 6050 include native support for all BACnet features. There are also improvements to the memory architecture to allow for larger, higher fidelity applications, enabling creation of extensive systems. The FT 6050 is supported by the SmartServer IoT’s BACnet and LON router and network managers, IzoT Net Server, an open platform software for creating and managing a network of devices and the IzoT Commissioning Tool, a GUI for creating a device network.