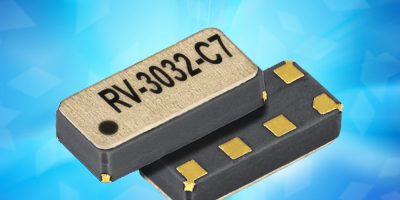

Claimed to offer the world’s best time accuracy across industrial temperature range at low current consumption, the RV-3032-C7 real time clock (RTC) module has been released by Micro Crystal. The compact RTC module has a custom IC and integrated quartz crystal resonator and sets new standards in size, claims the company. It is half the footprint of a uSOP-8 package, with no additional external components required. It is also claimed to offer the best accuracy (±0.26 s/day at -40 to +85 degrees C operating temperature). Low current consumption (160nA timekeeping mode) and power management capabilities are other features.

The RV-3032-C7 is suitable for applications requiring always-on timekeeping functions, as well as compliance to stringent clock accuracy over time, wide temperature range, and long battery life. Typical examples are smart metering and other similar industrial or consumer applications, such as wearables and IoT devices.

Power management features include a wide supply voltage range (1.2 to 5.5V), automatic backup switch, versatile charge pump and programmable trickle charger. The RTC module can be coupled with a small sized, low capacity, rechargeable battery, or a low cost coin cell power unit which will reduce the overall dimensions and the manufacturing cost of the end product while optimising the life of the battery, advises Micro Crystal.

The RV-3032-C7 includes a quartz-based digital temperature controlled crystal oscillator (DTCXO).

“The design team has applied their 40 years’ of frequency control expertise to develop [the module] . . . . Besides all the standard RTC features, it includes multiple extra functions, like data protection through password, and MHz output frequency, now available for the first time in the market in such a tiny device,” said Hans-Rudolf Gottier, CEO of Micro Crystal.

“The RV-3032-C7 RTC will definitely help engineers in developing next generations of smart products,” he continued. “The availability of a programmable high frequency clock output to drive the central MCU, and access to the high-resolution thermometer, used for accurate thermal compensation and allows setting temperature threshold alarms with interrupt function, will support numerous unique and new applications,” he said.

The RV-3032-C7 is hermetically sealed in a compact reflow solderable DFN ceramic package, measuring 3.2 x 1.5 x 0.8mm. It is RoHS/lead-free-compliant and AEC-Q200 qualified.