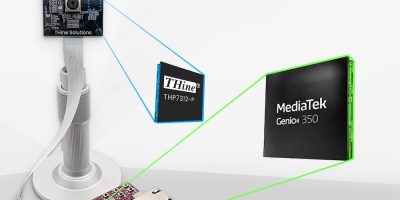

The THEIA-CAM 13Mpixel PDAF [phase detection autofocus] camera kit by THine Solutions is designed to interface to OLogic’s Pumpkin i350 and Pumpkin i500 evaluation kits. The kit consists of the THSCP101THEIA-CAM camera, which provides high resolution image streaming. The Pumpkin evaluation kits are based on MediaTek’s Genio 350 and Genio 500 SoC, providing edge processing platforms for AI and IoT systems.

The THSCP101 kit is based on THine’s THP7312-P image signal processor (ISP) and Sony’s IMX258 13MP CMOS PDAF image sensor. It includes all items required to interface with the Pumpkin evaluation kits, including a camera board in an acrylic case, a flat flexible cable, an adapter board to support two MIPI CSI-2 ports on the Pumpkin and an available software driver to stream and control images.

The THEIA-CAM 13Mpixel PDAF camera kit’s optimised ISP firmware provides best in class image quality and quick autofocus using PDAF technology, said THine. The performance of each kit is repeatable ensuring it can be used in high volume production; the images parameters of each image sensor is characterised and calibrated to compensate for variation from sensor to sensor.

All the Linux files and reference circuit schematics are available to customers. Customers requiring other image performance features can access a GUI-based software development tool that customises the ISP firmware.

According to Thine, the THSCP101 accelerates MediaTek Genio platform customers’ time to market without expensive initial costs or additional effort for developing embedded camera systems.

Tak Iizuka, chief solution architect of THine Solutions, commented: “MediaTek customers can now just plug the THSCP101 to Pumpkin [evaluation kits] and then see the … image quality just in a few minutes.”

“It is quite a breakthrough for our solution offerings,” said Ted Larson, CEO of OLogic. “We saw many customers who struggled to integrate high resolution cameras. Despite many camera-related components available in the market, it was almost impossible for them to even perform decent colour tuning before going into production.”

Stéphane Le Provost, senior director of technology at MediaTek, added: “This kit makes it simpler for customers to include camera systems in their products without having to manage the long and expensive process of developing and producing them from scratch.”

The THSCP101 is available for purchase at OLogic’s online store and Digi-Key.